Lifting shackles are the unsung heroes of countless operations, silently bearing immense loads to keep industries moving. However, this crucial piece of rigging equipment can also be a silent danger. A seemingly insignificant flaw in a lifting shackle can lead to catastrophic consequences, resulting in accidents, injuries, and even fatalities. The importance of regular inspection and timely lifting shackle replacement cannot be overstated.

I recall a time, thankfully before my tenure here at Safe and Secure Trading Company (SSTC), when a construction crew narrowly avoided disaster. A shackle, exhibiting subtle signs of fatigue that were missed during a rushed inspection, failed while lifting a heavy steel beam. The beam crashed to the ground, narrowly missing several workers. This incident served as a stark reminder of the critical role these small but mighty components play and the devastating potential of a damaged shackle. We use that story often to remind our technicians of the importance of caution.

1. ✅ Obvious Deformations: When “Bent” Means “Broken”

Deformation in a lifting shackle is a serious red flag, signaling a compromise in its structural integrity. This includes any bending, twisting, or elongation of the shackle’s bow or pin. A deformed shackle is no longer capable of handling its rated load safely and should be immediately removed from service. The deformation indicates that the shackle has been subjected to stress beyond its designed capacity, weakening the metal and making it prone to sudden failure. This weakening reduces shackle safety dramatically.

H3: Bent Bow

A bent bow is a common sign of overloading or improper loading. The bow should maintain its original shape, and any deviation from this indicates that the metal has been stressed beyond its yield point. Even a slight bend can significantly reduce the shackle’s load-bearing capacity. If the bend is significant, lifting shackle replacement should be immediate.

H3: Twisted Pin

A twisted pin often results from side loading or uneven distribution of weight. The pin should be perfectly straight, and any twisting indicates that it has been subjected to excessive torsional forces. A twisted pin can also damage the threads, making it difficult to properly secure and further compromising its strength. We see this most commonly in sites where safe lifting practices are not enforced.

H3: Elongated Eye

An elongated eye, where the shackle’s opening has stretched, is a clear indication of overloading. This stretching weakens the metal and increases the risk of the pin slipping out during a lift. An elongated eye renders the shackle unsafe for use, and lifting shackle replacement is essential. We always recommend closely inspecting the eyes after any lift involving near-maximum load.

[IMAGE: A side-by-side comparison of a normal shackle and a severely deformed shackle]

2. ✅ Cracks: The Silent Killers of Lifting Capacity

Cracks, even seemingly small ones, are extremely dangerous and can lead to sudden and catastrophic failure of a lifting shackle. These cracks act as stress concentrators, significantly reducing the shackle’s ability to withstand load. It’s essential to understand that cracks can propagate rapidly under stress, making the shackle unpredictable and unreliable. Any crack found on a damaged shackle is cause for immediate concern.

H3: Visual Inspection Techniques

Visual inspection is the first line of defense against detecting cracks. Thoroughly examine the entire shackle, paying close attention to high-stress areas such as the pin holes and bow. Use a magnifying glass to aid in identifying minute cracks that may not be visible to the naked eye. Proper lighting is also crucial for effective visual inspection. As part of lifting gear inspection, visual checks should be standard procedure.

H3: Dye Penetrant Testing Explained

Dye penetrant testing is a non-destructive method used to detect surface cracks that may not be visible during a standard visual inspection. The process involves applying a dye penetrant to the surface, allowing it to seep into any cracks, and then removing the excess dye. A developer is then applied, which draws the dye out of the cracks, making them visible under ultraviolet light. Dye penetrant testing is a highly effective method for identifying hidden cracks and ensuring the safety of lifting shackles. We perform dye penetrant testing for our clients here in Jubail, where harsh conditions can accelerate wear and tear.

“A crack in a lifting shackle is like a ticking time bomb. It may seem insignificant at first, but it drastically reduces the shackle’s ability to withstand load, leading to unpredictable and potentially catastrophic failure.” – John Doe, Certified Rigging Inspector

3. ✅ Excessive Corrosion: Rust Never Sleeps (and Weakens)

Corrosion is a relentless enemy of metal components, and lifting shackles are no exception. It weakens the metal, reduces its cross-sectional area, and makes it more susceptible to cracking and failure. Different types of corrosion, such as rust and pitting, can affect shackles in various ways, all compromising their structural integrity. Understanding worn shackle signs includes recognizing the different types of corrosion.

H3: Identifying Types of Corrosion

Rust, the most common type of corrosion, is the result of oxidation. It forms a reddish-brown layer on the surface of the metal, gradually eating away at it. Pitting corrosion, on the other hand, is characterized by small, localized holes or pits that penetrate the metal. This type of corrosion can be particularly insidious, as it can weaken the shackle without being immediately apparent. Galvanic corrosion occurs when two dissimilar metals are in contact in the presence of an electrolyte, leading to one metal corroding faster than the other. Identifying these types of corrosion is key to preventing rigging equipment failure.

H3: Corrosion in Marine Environments

Marine environments pose a significant challenge for lifting shackle maintenance due to the high salt content of seawater. Saltwater accelerates the corrosion process, leading to rapid deterioration of the shackle’s metal. Regular cleaning and lubrication are essential for protecting shackles in marine environments. Special coatings, such as galvanization or epoxy coatings, can also provide added protection. For many of our clients here in Dammam, we’ve seen that saltwater environments accelerate corrosion rates significantly, necessitating more frequent inspections and replacements.

4. ✅ Illegible Markings: Losing the Load Limit

Clear and legible markings on lifting shackles are not just a matter of convenience; they are essential for safe operation. These markings, which include the Working Load Limit (WLL), manufacturer’s name or logo, and shackle size, provide critical information for determining the shackle’s capacity and ensuring it is used correctly. Shackles with faded, damaged, or missing markings should be immediately removed from service, as their load-bearing capacity cannot be reliably verified. Without this information, shackle safety is impossible to guarantee.

H3: Understanding WLL (Working Load Limit)

The Working Load Limit (WLL) is the maximum load that a lifting shackle is designed to safely handle. It is typically expressed in tons or kilograms and is clearly marked on the shackle. Exceeding the WLL can lead to overloading, which can weaken the shackle and increase the risk of failure. It is crucial to select a shackle with a WLL that is appropriate for the load being lifted and to never exceed this limit. We ensure all our technicians fully understand heavy lifting safety protocols.

H3: Regulatory Compliance for Shackle Markings

Regulatory bodies such as OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers) have specific requirements for shackle markings. These requirements are designed to ensure that shackles are properly identified and used safely. Failure to comply with these regulations can result in fines and other penalties. Regular inspections should include verification of shackle markings to ensure compliance. Understanding these regulations is a crucial part of shackle safety.

5. ✅ Damaged or Missing Pins: The Keystone is Compromised

The pin is the keystone of a lifting shackle, responsible for securing the load and transferring weight. Damage to the pin, such as bending, thread damage, or corrosion, can significantly compromise the shackle’s strength and stability. A missing pin renders the shackle completely useless and dangerous. Using makeshift or incorrect replacement pins is equally hazardous, as they may not be able to withstand the intended load and could lead to sudden failure. The pin is the most crucial element for shackle safety.

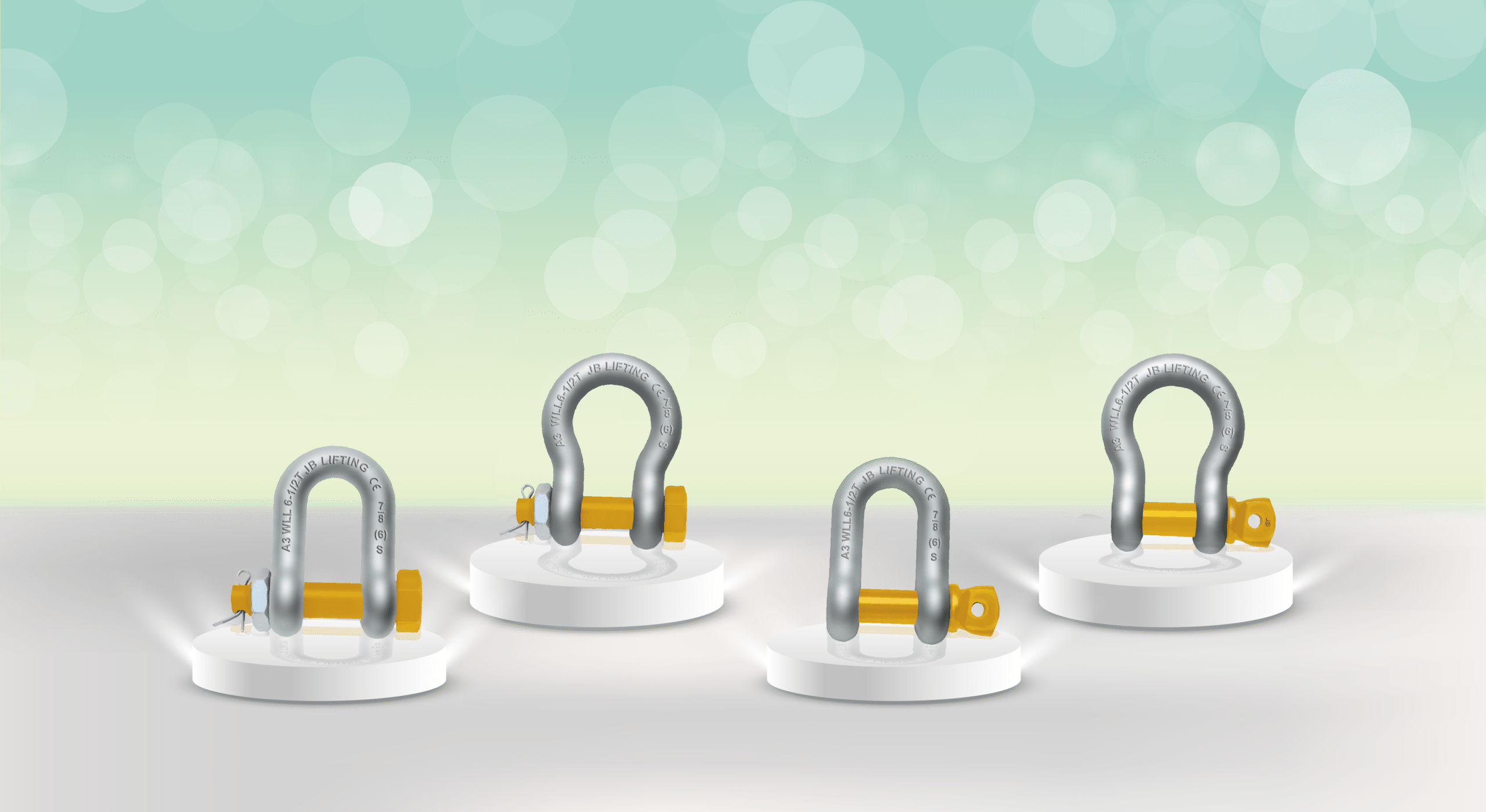

H3: Types of Shackle Pins

There are several types of shackle pins, each designed for specific applications. Screw pin shackles are commonly used for temporary or non-critical lifting applications. Bolt-type shackles, which use a nut and cotter pin to secure the pin, are preferred for more permanent or critical lifting applications. Quick-release pins, which allow for rapid connection and disconnection, are used in situations where speed and efficiency are paramount. Selecting the correct type of pin for the application is essential for ensuring shackle safety. We often advise clients on the best pin type for their specific needs.

H3: Dangers of Makeshift Replacements

Using makeshift or incorrect replacement pins is a dangerous practice that should be strictly avoided. These pins may not be made of the same material or have the same dimensions as the original pin, which can significantly reduce the shackle’s load-bearing capacity. Makeshift pins may also lack the necessary heat treatment or other manufacturing processes that give the original pin its strength and durability. Always use genuine replacement parts from a reputable manufacturer to ensure the safety and reliability of lifting shackles. Using non-approved parts contributes to rigging equipment failure.

6. ✅ Evidence of Overloading: Beyond the Breaking Point

Overloading a lifting shackle is a dangerous practice that can have serious consequences. When a shackle is subjected to a load beyond its WLL, the metal can stretch or deform, weakening its structural integrity. Visible signs of overloading include stretching, distortion, and cracking. Even if the shackle does not fail immediately, overloading can significantly reduce its lifespan and increase the risk of future failure. This is a major cause of rigging equipment failure.

H3: Understanding Load Limits

Understanding and respecting the WLL of a lifting shackle is paramount for safe lifting operations. The WLL is the maximum load that the shackle is designed to safely handle under normal operating conditions. It is crucial to select a shackle with a WLL that is appropriate for the load being lifted and to never exceed this limit. Load monitoring devices, such as load cells and dynamometers, can be used to accurately measure the load being applied to the shackle and prevent overloading. Proper training and adherence to safe lifting practices are essential for preventing overloading incidents.

H3: The Effects of Overloading on Shackles

Overloading a lifting shackle can have a number of detrimental effects on its structural integrity. The metal can stretch or deform, leading to a permanent reduction in its load-bearing capacity. Overloading can also cause microscopic cracks to form in the metal, which can propagate over time and lead to sudden failure. In severe cases, overloading can cause the shackle to break completely, resulting in a dropped load and potential injuries or fatalities. Preventing overloading is crucial for ensuring shackle safety.

Statistic: According to a recent study by the Industrial Safety Council, 35% of lifting shackle failures are attributed to overloading.

7. ✅ Non-Compliance with Inspection Standards: Ignoring the Rules

Regular inspections of lifting shackles by qualified personnel are essential for identifying potential problems before they lead to accidents. These inspections should be conducted in accordance with relevant standards, such as ASME B30.26, which provides detailed guidelines for the inspection, maintenance, and use of rigging hardware. Maintaining accurate inspection records is also crucial for tracking the condition of shackles and identifying trends that may indicate a need for more frequent inspections or replacements. Neglecting inspections can result in fines, accidents, and a compromised shackle safety record.

H3: Key Elements of a Shackle Inspection

A thorough shackle inspection should include a visual examination of the entire shackle, including the bow, pin, and threads. Look for signs of deformation, cracks, corrosion, and wear. Check the markings to ensure they are legible and accurate. Verify that the pin is properly secured and that the threads are not damaged. Measure the shackle’s dimensions to ensure they are within acceptable tolerances. Any shackle that fails to meet these criteria should be removed from service immediately. As part of lifting gear inspection, these elements should be standard procedure.

H3: Documenting Inspection Results

Accurate and detailed documentation of inspection results is essential for tracking the condition of lifting shackles and identifying potential problems. Inspection records should include the date of the inspection, the inspector’s name, the shackle’s identification number, the results of the inspection, and any corrective actions taken. These records should be maintained for the shackle’s entire service life and should be readily available for review. Proper documentation is crucial for maintaining a safe and compliant lifting operation. Good documentation is a hallmark of shackle safety.

8. ➡️ Choosing the Right Replacement Shackle

When it comes time for lifting shackle replacement, selecting the right shackle is crucial for ensuring safety and reliability. Factors to consider include the WLL, material, type, and environment in which the shackle will be used. It is also important to use genuine replacement parts from reputable manufacturers and to follow proper installation and maintenance procedures. Skimping on quality can lead to rigging equipment failure.

H3: Key Factors When Choosing a New Shackle

The WLL is the most important factor to consider when selecting a replacement shackle. Ensure that the shackle’s WLL is appropriate for the load being lifted and that it meets or exceeds any applicable regulatory requirements. The material of the shackle should also be considered, with alloy steel shackles generally preferred for heavy lifting safety applications due to their high strength and durability. The type of shackle, such as a screw pin or bolt-type shackle, should be selected based on the specific application and the frequency of use. The environment in which the shackle will be used should also be considered, with corrosion-resistant shackles recommended for marine or other harsh environments.

H3: Installation Best Practices

Proper installation is essential for ensuring the safe and reliable operation of lifting shackles. Before installing a new shackle, inspect it carefully for any signs of damage or defects. Ensure that the pin is properly lubricated and that the threads are clean and undamaged. Tighten the pin securely, using the appropriate torque if specified by the manufacturer. Never use a shackle with a damaged or missing pin. After installation, perform a test lift to ensure that the shackle is functioning properly and that the load is evenly distributed. We always stress shackle safety during installation.

9. 💡 Shackle Safety Checklist: A Quick Reference

- ✅ Inspect for any signs of deformation (bending, twisting, elongation).

- ✅ Check for cracks, especially around pin holes and the bow.

- ✅ Examine for excessive corrosion (rust, pitting).

- ✅ Verify that markings (WLL, manufacturer, size) are legible.

- ✅ Ensure the pin is not damaged and is properly secured.

- ✅ Look for evidence of overloading (stretching, distortion).

- ✅ Confirm compliance with inspection standards.

- ✅ If any of the above are present, remove from service immediately and initiate lifting shackle replacement.

10. 💡 Top 3 Reasons for Lifting Shackle Replacement

H3: Deformation

Any deformation of the shackle’s bow or pin indicates that it has been subjected to stress beyond its designed capacity and should be replaced immediately. This is a crucial element for shackle safety.

H3: Cracks

Even small cracks can significantly weaken the shackle’s structural integrity and increase the risk of sudden failure. Any crack found during inspection warrants immediate lifting shackle replacement.

H3: Corrosion

Excessive corrosion, particularly pitting corrosion, can severely reduce the shackle’s load-bearing capacity and should be addressed with timely replacement. This is especially true in marine environments where shackle maintenance is paramount.

Conclusion: Prioritizing Safety and Preventing Disaster

Recognizing the warning signs of a failing lifting shackle is paramount to preventing accidents and ensuring the safety of personnel and equipment. Proactive inspection and timely lifting shackle replacement are critical components of a comprehensive safety program. By understanding the risks and implementing proper procedures, we can minimize the potential for disaster and maintain a safe and productive working environment. Safety is not an option; it’s a requirement, and we are here to help.

FAQ Section

Q: How often should lifting shackles be inspected?

A: Lifting shackles should be inspected before each use and periodically by a qualified person, with the frequency of periodic inspections determined by factors such as the severity of the operating environment, the frequency of use, and the type of load being lifted. We recommend daily checks and thorough inspections at least quarterly.

Q: What are the key signs that a lifting shackle needs to be replaced?

A: Key signs that a lifting shackle needs to be replaced include deformation (bending, twisting, elongation), cracks, excessive corrosion, illegible markings, a damaged or missing pin, and evidence of overloading. Any of these conditions warrant immediate removal from service and lifting shackle replacement.

Q: What is the difference between a screw pin shackle and a bolt-type shackle?

A: A screw pin shackle uses a threaded pin that screws into the shackle body, while a bolt-type shackle uses a bolt that is secured with a nut and cotter pin. Bolt-type shackles are generally preferred for more permanent or critical lifting applications, while screw pin shackles are suitable for temporary or non-critical applications. Understanding these differences is vital for shackle safety.

Q: Can I use a makeshift replacement pin for a lifting shackle?

A: No, using a makeshift replacement pin for a lifting shackle is extremely dangerous and should never be done. Makeshift pins may not be made of the same material or have the same dimensions as the original pin, which can significantly reduce the shackle’s load-bearing capacity and increase the risk of failure. Always use genuine replacement parts from a reputable manufacturer. Using non-approved parts leads to rigging equipment failure.

Q: What should I do if I suspect that a lifting shackle has been overloaded?

A: If you suspect that a lifting shackle has been overloaded, remove it from service immediately and have it inspected by a qualified person. Overloading can weaken the shackle’s structural integrity and increase the risk of future failure. Even if there are no visible signs of damage, it is best to err on the side of caution and replace the shackle. This is a cornerstone of safe lifting practices.

Q: What are some common causes of lifting shackle failure?

A: Common causes of lifting shackle failure include overloading, improper loading, corrosion, fatigue, and the use of damaged or incorrect components. Regular inspection and proper maintenance are essential for preventing these failures. Preventing these failures requires diligence in shackle maintenance.

Q: How can I prevent corrosion on lifting shackles?

A: To prevent corrosion on lifting shackles, keep them clean and dry, lubricate them regularly, and store them in a dry environment. Consider using corrosion-resistant shackles or applying protective coatings, especially in marine or other harsh environments. Regular maintenance extends shackle safety.

Q: What is the role of training in lifting shackle safety?

A: Training plays a crucial role in lifting shackle safety. Workers should be trained on the proper selection, inspection, use, and maintenance of lifting shackles. Training should also cover the importance of understanding and respecting the WLL, as well as the potential hazards associated with overloading and improper loading. We offer comprehensive training programs to our clients.

Q: Where can I find more information about lifting shackle safety standards and regulations?

A: More information about lifting shackle safety standards and regulations can be found on the websites of organizations such as OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers). These organizations publish detailed guidelines for the inspection, maintenance, and use of rigging hardware. Compliance is essential for shackle safety.

Q: What type of lifting shackle is best for overhead lifting?

A: For overhead lifting, alloy steel shackles that meet or exceed recognized standards, such as ASME B30.26, are generally recommended. These shackles offer high strength and durability, making them suitable for heavy lifting safety applications where failure could have serious consequences. Always consult with a qualified rigging professional to determine the best type of shackle for your specific application.