- Desiccant

- Safety Shoes

- Load Monitoring

- Fall Protection

- Wire Rope Fittings

- Hooks

- Lifting Slings

- Rigging Accessories

- Shackles

- Lifting Clamps

- Material Handling Equipment

- Matterport Cameras

- Others

- Ropes

- Block / Hoist / Trolley

- Rigging Screws

- Cargo Accessories

- Snatch Block / Pulley

- Chains

- Stainless Steel Accessories

- Spreader Beam And Bar

Free shipping over 2000 SAR

- Home

- ShopHot

- Block / Hoist / Trolley

- Chains

- Fall Protection

- Hooks

- Lifting Clamps

- Shackles

- Cargo Accessories

- Lifting SlingsHot

- Wire Rope Fittings

- Ropes

- Snatch Block / Pulley

- Spreader Beam & Bar

- Material Handling Equipment

- Rigging Screws

- Lifting And Rigging Accessories

- Stainless Steel Accessories

- Desiccant

- Safety Shoes

- About

- About Us

- Sell Your Brand

- Become Our Sale Agent

- Exclusive Distributor Of Bull Rope Products In KSA

- Exclusive Distributor Of JB Lifting Products In KSA

- Exclusive Distributor of Modulift products in KSA

- Exclusive Distributor Of Safety Jogger Products In KSA

- All Exclusive Distributorship

- Procedure and Policies

- Services

- Calculators

- Brands

- Blog

- Contact

- Desiccant

- Safety Shoes

- Load Monitoring

- Fall Protection

- Wire Rope Fittings

- Hooks

- Lifting Slings

- Rigging Accessories

- Shackles

- Lifting Clamps

- Material Handling Equipment

- Matterport Cameras

- Others

- Ropes

- Block / Hoist / Trolley

- Rigging Screws

- Cargo Accessories

- Snatch Block / Pulley

- Chains

- Stainless Steel Accessories

- Spreader Beam And Bar

No products in the cart.

Return To ShopFree shipping over 2000 SAR

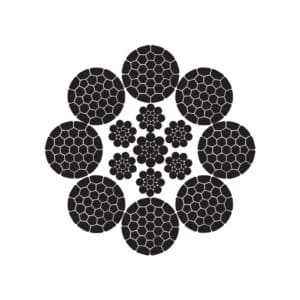

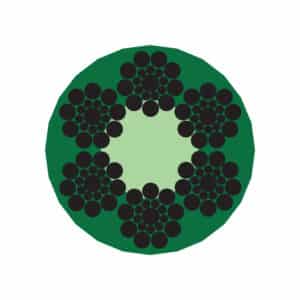

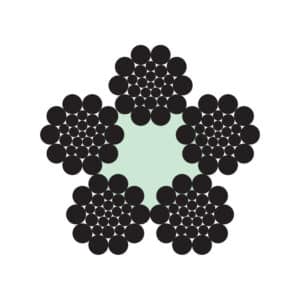

Steel wire rope, a vital component across industries, comes in various categories tailored to distinct needs. Its construction varies, with spiral strands, fiber core, and other configurations impacting strength and flexibility. Materials like stainless steel, galvanized steel, and carbon steel offer corrosion resistance. Diameter choices match load capacities, from light to heavy-duty. Specific applications like cranes, aircraft, elevators, marine, and mining ropes meet industry needs. Lay direction affects rotation resistance. Additional features like coatings, lubrication, and high-temperature resistance customize use. Compliance with safety standards ensures reliability. Understanding these categories aids in selecting the right steel wire rope for lifting, rigging, and anchoring. As a leading wire rope supplier in Saudi Arabia, we provide solutions with varying constructions including spiral strands, fiber core, and other configurations that impact strength and flexibility.

SELECTION OF WIRE ROPE?

Choosing the right steel wire rope might seem complicated, but it doesn’t have to be. Let’s break it down into simple steps to help you make the best choice for your job. Whether you need wire rope steel for heavy lifting, wire steel rope for industrial applications, or wire rope supplier in saudi arabia, this guide will help you find the perfect fit. Our ropes are globally sourced from leading manufacturers in Korea, UAE, Saudi Arabia, Japan, UK, and India, ensuring you receive the highest quality for every application.-

Understand Your Application

- Lifting and Hoisting: For heavy lifting with cranes or hoists, you need a strong and durable rope like 6x19 or 6x36 construction.

- Winching and Pulling: If you're using a winch system, flexible ropes like 7x19 are ideal because they handle bending well.

- Marine and Offshore: Given Dammam’s coastal location, ropes that resist corrosion, such as galvanized or stainless steel, are perfect for mooring lines and towing.

-

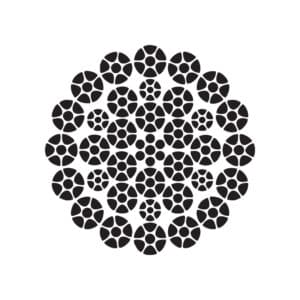

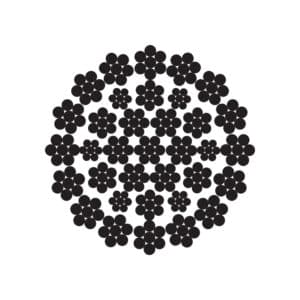

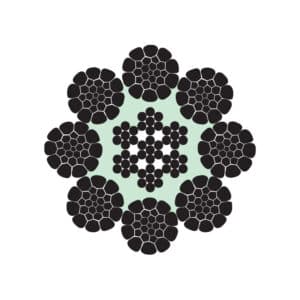

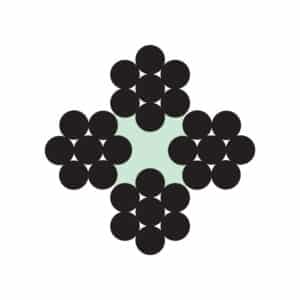

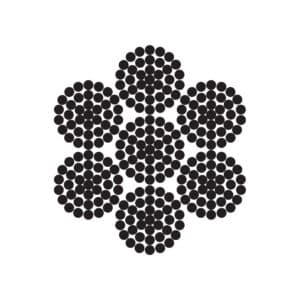

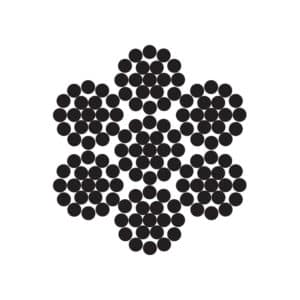

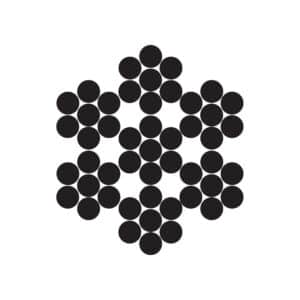

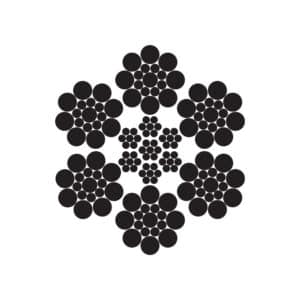

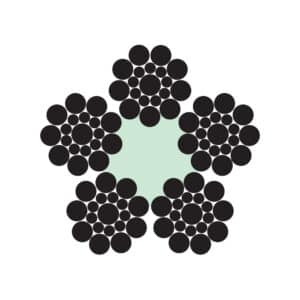

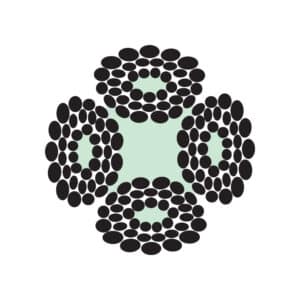

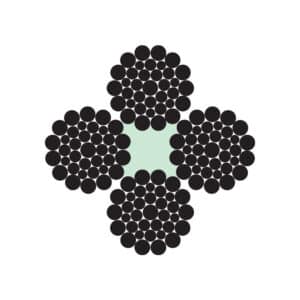

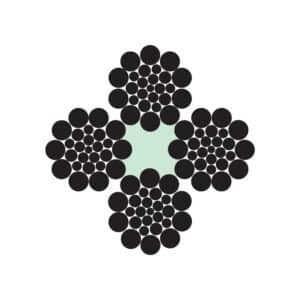

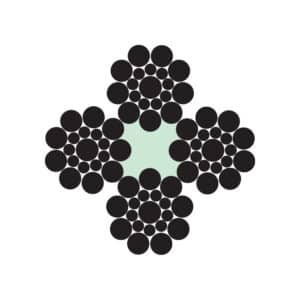

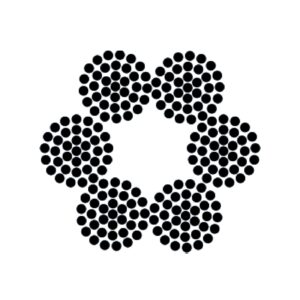

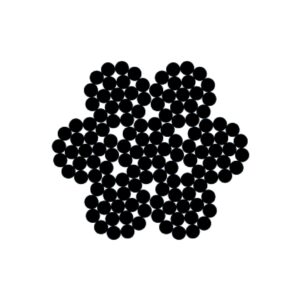

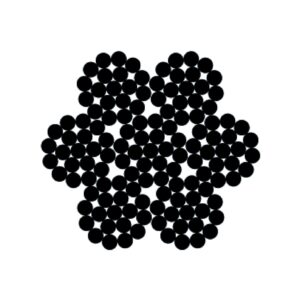

Choose the Right Rope Construction

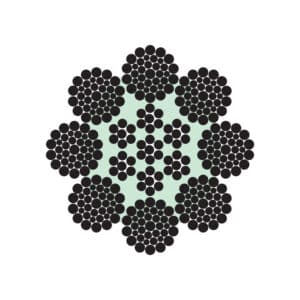

- 6x19 Construction: It has 6 strands with 19 wires each. It offers a good balance of strength and flexibility, making it suitable for general lifting.

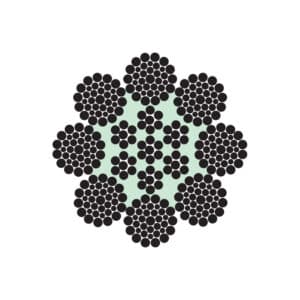

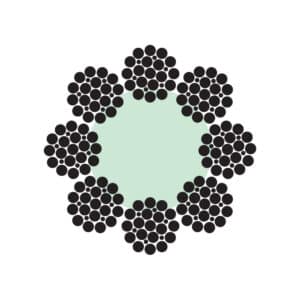

- 6x36 Construction: This rope is more flexible due to its higher wire count per strand. It’s ideal for applications that involve frequent bending, like pulleys.

- 7x19 Construction: Known for its high flexibility, this type is often used in winch cables and control systems.

-

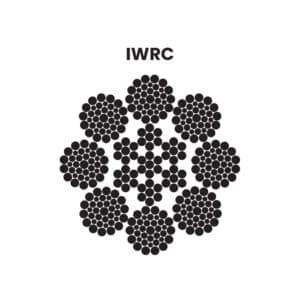

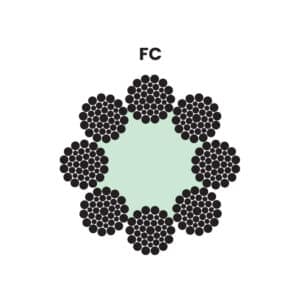

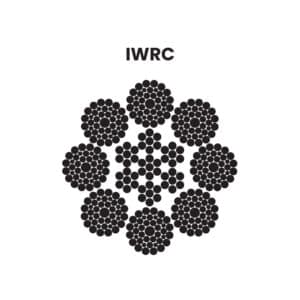

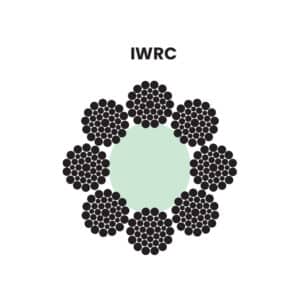

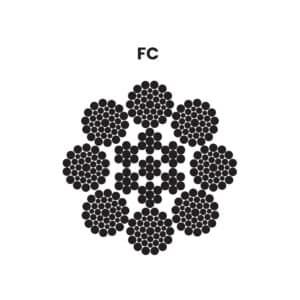

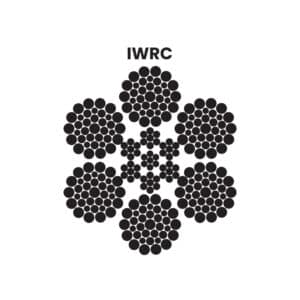

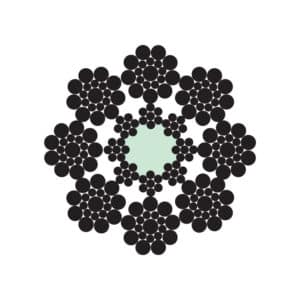

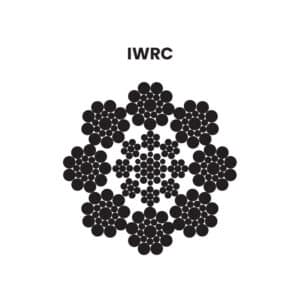

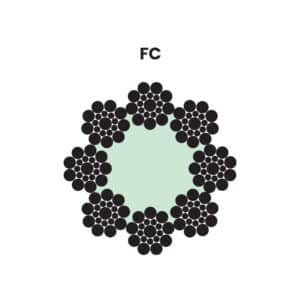

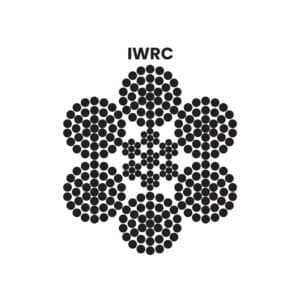

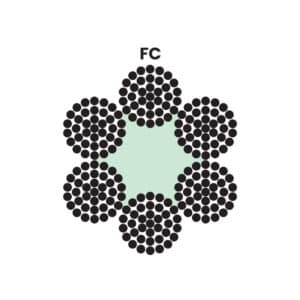

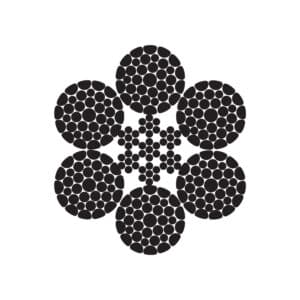

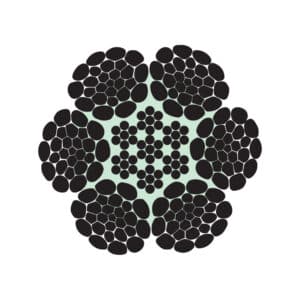

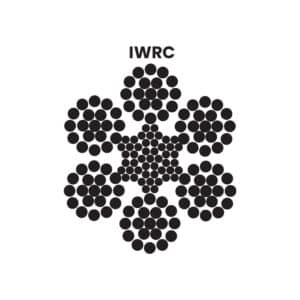

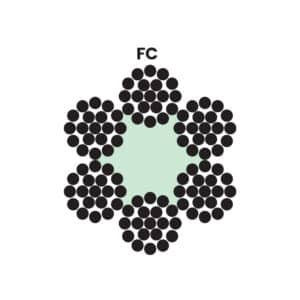

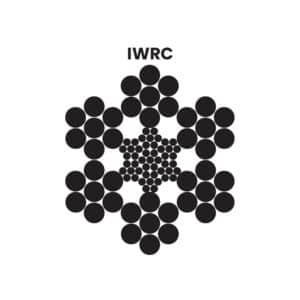

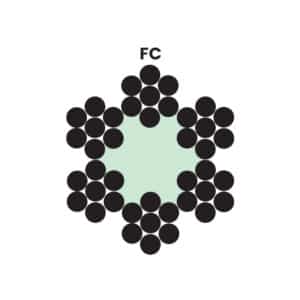

Select the Right Core Type

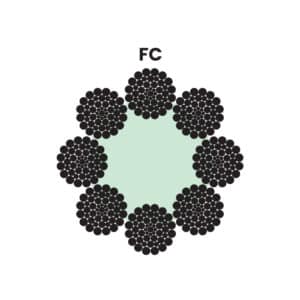

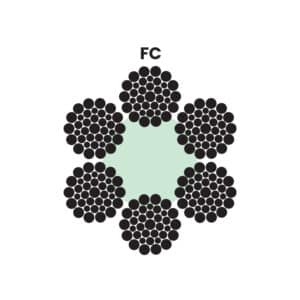

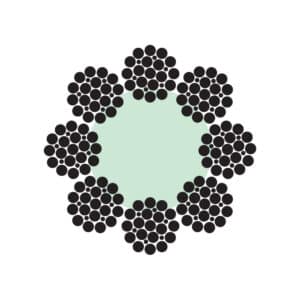

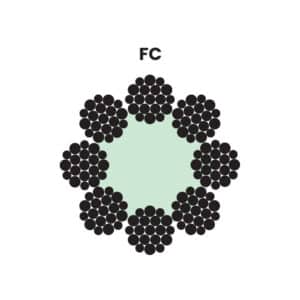

- Fiber Core (FC): Soft and flexible, but less strong. Suitable for light-duty tasks.

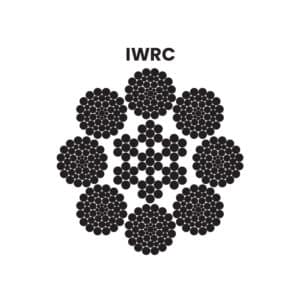

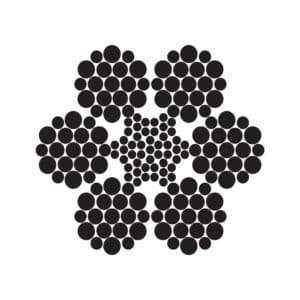

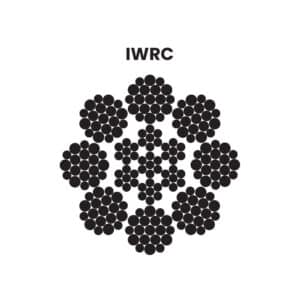

- Independent Wire Rope Core (IWRC): Made of steel, it offers superior strength and durability, perfect for heavy lifting.

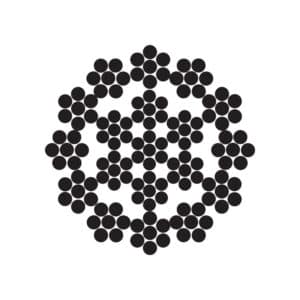

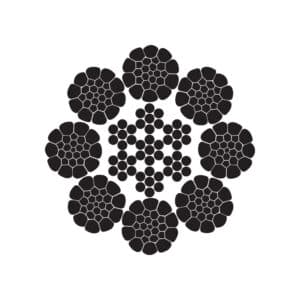

- Wire Strand Core (WSC): Provides a good balance of strength and flexibility, making it suitable for general lifting tasks.

-

Consider the Load Capacity

- Breaking Strength: The maximum force the rope can take before breaking.

- Working Load Limit (WLL): The safe weight the rope can handle during normal use. For construction projects in Dammam, where heavy materials are common, choosing a rope with an appropriate WLL is crucial to prevent accidents.

-

Think About Flexibility vs. Abrasion Resistance

- If your job involves frequent bending, like in pulleys or winches, choose a flexible rope with many thin wires per strand, such as 6x36.

- If the rope will be exposed to rough surfaces, opt for one with thicker wires, like 6x19, because it offers better abrasion resistance.

-

Select the Right Finish for the Environment

- Galvanized Steel: Coated to prevent rust, suitable for outdoor or coastal environments.

- Stainless Steel: Highly resistant to rust, making it the best choice for marine and offshore applications in places like Dammam.

- Bright Steel: Uncoated, best for indoor use where rust isn’t a concern.

-

Check for Rotation Resistance

-

Get Expert Help and Local Support

MEASURING THE ROPE DIAMETER : THE RIGHT WAY

Measuring the diameter of a steel wire rope might seem simple, but getting it right is crucial. Using the correct technique ensures you get the accurate size needed for safe and efficient operation. Here’s how to do it properly.The Correct Way to Measure

First, use a caliper with broad jaws that can cover at least two adjacent strands of the rope. Position the caliper so it measures across the outermost crowns (the highest points) of two opposite strands. This method gives you the true maximum diameter of the wire rope. It’s important because this measurement reflects the actual size needed for fitting into your equipment or pulleys.Common Mistake to Avoid

Avoid measuring across the valleys (the lower points between strands). This mistake leads to a smaller reading and can result in choosing an undersized rope. Using a rope that’s too small can cause slippage, reduce load capacity, and even lead to premature failure.Why Accurate Measurement Matters

Getting the diameter right is essential. A correct fit ensures the rope performs safely under load without slipping or causing damage. Inaccurate measurements can result in choosing a rope that doesn’t fit your equipment properly, affecting overall safety and efficiency.Local Support in Dammam, Jubail, and Riyadh

Not sure about the measurement? Don’t worry, we’re here to help. Our team in Dammam, Jubail, and Riyadh can provide on-site support. We’ll assist you in selecting the right steel wire rope size for your project, ensuring everything runs smoothly and safely.Contact Us Today!

Need assistance with measuring or choosing the correct steel wire rope? Get in touch with us now! We offer expert advice and high-quality products to meet your needs. Let’s work together to make your operations safer and more efficient.UNDERSTANDING WIRE ROPE LAYS

Choosing the right type of steel wire rope is essential for safe and efficient operations. Let’s look at the main types of rope lay, their acronyms, and how they differ.1. Right Hand Ordinary Lay (RHOL)

In this type, the strands twist to the right, similar to the threads of a screw. It’s the most common rope lay because it’s reliable and easy to handle. You’ll often see RHOL ropes used in standard lifting, pulling, and construction tasks.2. Left Hand Ordinary Lay (LHOL)

For this lay, the strands twist to the left. It’s less common but very useful in specific setups. Some machines need LHOL ropes to counteract their rotation and prevent the rope from unwinding. It’s ideal when you need a rope that won’t spin or twist under load.3. Right Hand Lang's Lay (RHLL)

In RHLL ropes, both the strands and wires twist to the right in the same direction. This design makes the rope more resistant to wear and tear. It’s perfect for heavy-duty applications, like mining and crane operations, where the rope faces a lot of friction and abrasion.4. Left Hand Lang's Lay (LHLL)

LHLL ropes have both strands and wires twisting to the left. It offers the same benefits as RHLL, like better resistance to wear. However, it’s used when the machine or application requires a left-hand twist to match its movement or to prevent the rope from loosening.Choosing the Right Lay for Your Needs

Most machines and equipment use Right Hand Ordinary Lay (RHOL) because it’s versatile and easy to work with. However, if you have specialized machinery or need to prevent the rope from unwinding, Left Hand Ordinary Lay (LHOL) might be the better choice. For high-abrasion environments or heavy-duty tasks, Lang's Lay types like RHLL and LHLL are often preferred due to their increased durability.Expert Help in Dammam, Jubail, and Riyadh

If you’re not sure which type of steel wire rope is best for your project, we’re here to help. Our team in Dammam, Jubail, and Riyadh can guide you in choosing the right rope for your specific needs. We can even visit your site to assess the requirements and recommend the best options.Let’s Get Started!

Need help selecting the right steel wire rope? Contact us today for expert advice. We’re ready to support your operations with top-quality products and local expertise, ensuring your projects run smoothly and safely.SAFETY FACTORS FOR ROPE: A SIMPLE GUIDE

Choosing the right safety factor for steel wire ropes is crucial to ensure safety and reliable performance. However, it can be tricky because the ideal safety factor depends on many factors. These include the load's weight, the speed of the rope's operation, the type of fittings, and the length of the rope. The arrangement and size of sheaves and drums also play a significant role. To simplify this process, here are the minimum recommended safety factors for common applications:| Purpose | Minimum Safety Factor |

| Elevator | 10 |

| Cranes, Hoists, Derricks, Slings | 6 |

| Guy Wires, Horizontal Pulls, Traction | 4 |

| Main Wire in Aerial Ropeways | 3 |

Why These Safety Factors?

- Elevators need a high safety factor of 10 because they carry people, and ensuring maximum safety is essential.

- Cranes, hoists, and slings use a factor of 6 due to the heavy loads they lift regularly.

- For guy wires and horizontal pulls, a safety factor of 4 is typically sufficient, balancing strength and efficiency.

- Aerial ropeways can operate safely with a factor of 3, given their specific design and controlled environment.

Get Local Expertise in Dammam, Jubail, and Riyadh

If you’re unsure about selecting the right steel wire rope or need help determining the appropriate safety factor, we’re here to assist! Our experienced team in Dammam, Jubail, and Riyadh can provide personalized guidance based on your specific needs. Contact us today to ensure your operations are safe and efficient with the best products and advice tailored for you.STEEL WIRE ROPE APPLICATIONS

Steel wire ropes are incredibly versatile and widely used in many industries. Known for their strength, flexibility, and durability, they play a crucial role in a growing industrial hub like Dammam. We partner with premium suppliers across Korea, Japan, UAE and Europe to deliver ropes that meet the exacting demands of Saudi industries, from coastal marine projects to desert oil fields.-

Construction Industry

-

Mining Industry

-

Marine and Offshore Industries

-

Oil and Gas Industry

-

Forestry and Agriculture

-

Transportation Industry

-

Entertainment Industry

-

Safety and Rescue Operations

STEEL WIRE ROPE MAINTENANCE

Steel wire ropes are strong and reliable, but they require regular maintenance to ensure their durability and safety. Without proper care, they can wear out quickly, leading to costly repairs and potential safety hazards. Fortunately, with a few simple steps, you can keep your ropes in great condition for a longer time.-

Regular Inspections: Spot Issues Early

-

Lubrication: Keep the Rope Moving Smoothly

-

Proper Handling and Storage: Protect the Rope

-

Avoid Overloading and Shock Loading: Prevent Damage

-

Rotation and Replacement: Stay Proactive

-

Environmental Protection: Choose the Right Rope

WIRE ROPE STRENGTH?

Steel wire ropes are known for their incredible strength and durability. They play a crucial role in various industries that require lifting, pulling, or securing heavy loads. In Dammam, Saudi Arabia, where construction, oil and gas, and marine activities are widespread, having strong and reliable steel wire ropes is essential. We provide high-quality steel wire ropes tailored to meet the needs of local businesses.1. Breaking Strength

Breaking strength, or ultimate tensile strength, is the maximum force a steel wire rope can handle before it breaks. This is a key factor when choosing the right rope for your job. For instance, in Dammam’s busy construction sites, ropes used in cranes and hoists need a high breaking strength to safely lift heavy materials.- How It Works: The breaking strength is calculated based on the total strength of the individual wires and the rope’s overall cross-sectional area. This gives an idea of how much weight the rope can support before it fails.

2. Working Load Limit (WLL)

The Working Load Limit (WLL) is the safe maximum weight the rope can handle during regular use. It is usually set at a fraction of the breaking strength (about 1/5th or 1/6th). This helps ensure safety and prevent overloading.- Why It Matters: Operating beyond the WLL can damage the rope and reduce its lifespan. It can also lead to accidents. That’s why we always recommend following the WLL guidelines to keep operations safe and efficient.

3. Factors Affecting Strength

- Material: The type of steel used affects the rope’s strength. High-carbon steel wires offer excellent strength and flexibility. Stainless steel wires are highly resistant to corrosion, making them ideal for Dammam’s coastal and marine environments.

- Rope Construction: The arrangement of wires and strands impacts the rope’s performance.

- 6x19 Construction: This type is strong and flexible, suitable for general lifting and hoisting.

- 6x36 Construction: It is more flexible, ideal for situations where the rope needs to bend frequently.

- Diameter: A thicker rope has a higher breaking strength. For example, a 16mm rope is usually stronger than a 10mm rope of the same type.

4. Wire Rope Grades and Strength

Steel wire ropes come in different grades based on their tensile strength:- EIPS (Extra Improved Plowed Steel): This grade offers good strength and is widely used in heavy-duty applications in Dammam’s construction projects.

- EEIPS (Extra Extra Improved Plowed Steel): It provides even greater strength, making it suitable for demanding tasks like lifting heavy equipment on oil rigs.

| ISO | Metric | American |

| 2160 N/mm² | 220 kgf/mm² | Extra Extra Improved Plow Steel (EEIPS) |

| 1960 N/mm² | 200 kgf/mm² | Extra Improved Plow Steel (EIPS) |

| 1770 N/mm² | 180 kgf/mm² | Improved Plow Steel (IPS) |

| 1570 N/mm² | 160 kgf/mm² | Plow Steel (PS) |

| 1420 N/mm² | 145 kgf/mm² | Traction Steel |

5. Safety Factor

The safety factor is a built-in margin that ensures the rope can handle more than its expected load. For most applications in Dammam, a safety factor of 5:1 is common. This means the rope’s breaking strength is five times greater than the actual working load.6. Maintaining Strength and Durability

Regular maintenance is key to preserving the rope’s strength. Inspections for wear, corrosion, and broken wires help identify issues early. Proper lubrication reduces friction and wear, extending the rope’s life. It’s also important to store the rope properly, away from moisture and corrosive substances. We offer expert advice and support in Dammam to help you maintain your steel wire ropes effectively.WHY BULL ROPE IS THE PREFERRED CHOICE FOR CRANE OPERATORS ?

Steel wire ropes are essential components in various crane operations, offering strength, flexibility, and reliability for safe and efficient lifting. Bull Rope, a leading brand in the industry, provides high-quality steel wire ropes tailored to meet the specific needs of different crane types. Below is a detailed guide to their applications in various cranes, highlighting the suitability of Bull Rope products for each.-

Mobile Cranes

- Characteristics: High flexibility, strength, and abrasion resistance.

- Preferred Construction: 6x36 or rotation-resistant ropes (19x7).

- Applications: Lifting heavy materials in construction and industrial projects.

- Bull Rope Advantage: Bull Rope offers 6x36 and 19x7 constructions with superior flexibility and strength, ensuring safe and efficient lifting operations.

-

Elevators

- Characteristics: Smooth operation and long lifespan with high safety factors.

- Preferred Construction: 6x19 or 8x19.

- Applications: Passenger and freight elevators, especially in high-rise buildings.

- Bull Rope Advantage: Bull Rope's 6x19 and 8x19 constructions are designed for elevator applications, providing reliability and compliance with safety standards.

-

Onshore Drilling

- Characteristics: Durable, compacted, and resistant to rotation.

- Preferred Construction: Rotation-resistant ropes (19x7 or compacted).

- Applications: Hoisting and rigging equipment in drilling operations.

- Bull Rope Advantage: Bull Rope provides rotation-resistant and compacted ropes suitable for the demanding conditions of onshore drilling.

-

Sea Port Mobile Cranes

- Characteristics: Corrosion-resistant ropes for harsh marine environments.

- Preferred Construction: Hot-dip galvanized ropes or stainless steel (6x36 or 19x7).

- Applications: Loading and unloading cargo in sea ports.

- Bull Rope Advantage: Bull Rope's hot-dip galvanized and stainless steel ropes are engineered to withstand marine conditions, ensuring longevity and performance.

-

Boom Cranes

- Characteristics: High fatigue resistance and flexibility.

- Preferred Construction: 6x19 Seale or 6x36 filler wire.

- Applications: Construction and industrial lifting operations.

- Bull Rope Advantage: Bull Rope's 6x19 Seale and 6x36 filler wire constructions offer the necessary fatigue resistance and flexibility for boom crane operations.

-

Tower Cranes

- Characteristics: Anti-rotation ropes for stability and safety.

- Preferred Construction: 19x7 or 35x7.

- Applications: High-lift operations in urban construction projects.

- Bull Rope Advantage: Bull Rope's anti-rotation ropes, such as 19x7 and 35x7 constructions, ensure stability and safety in tower crane applications.

-

Overhead Cranes (Bridge Cranes)

- Characteristics: High-strength ropes with abrasion resistance for indoor and outdoor use.

- Preferred Construction: 6x36 or rotation-resistant ropes.

- Applications: Moving heavy loads in warehouses, factories, and shipyards.

- Bull Rope Advantage: Bull Rope provides 6x36 and rotation-resistant ropes designed for the rigorous demands of overhead crane operations.

-

Jib Cranes

- Characteristics: Flexible ropes with moderate strength, suitable for repetitive lifting.

- Preferred Construction: 6x19 or 6x36.

- Applications: Assembly lines, workshops, and loading docks.

- Bull Rope Advantage: Bull Rope's 6x19 and 6x36 constructions provide the necessary flexibility and strength for jib crane applications.

-

Crawler Cranes

- Characteristics: High-strength ropes with resistance to bending fatigue.

- Preferred Construction: 6x36 or compacted ropes.

- Applications: Heavy lifting in large construction or industrial projects.

- Bull Rope Advantage: Bull Rope offers 6x36 and compacted ropes engineered to handle the demanding conditions of crawler crane operations.

-

Floating Cranes (Crane Barges)

- Characteristics: Corrosion-resistant ropes for marine environments.

- Preferred Construction: Stainless steel or hot-dip galvanized ropes (6x36 or 19x7).

- Applications: Offshore construction, shipbuilding, and salvaging operations.

- Bull Rope Advantage: Bull Rope's stainless

-

Gantry Cranes (Portal and Semi-Gantry Cranes)

- Characteristics: Durable ropes with high tensile strength for repetitive operations.

- Preferred Construction: 6x36 or 6x19 Seale.

- Applications: Ports, rail yards, and container handling facilities.

- Bull Rope Advantage: Bull Rope provides abrasion-resistant 6x36 and 6x19 Seale constructions, perfect for high-cycle operations in gantry cranes.

-

Deck Cranes

- Characteristics: Compact and corrosion-resistant ropes for marine environments.

- Preferred Construction: Hot-dip galvanized or stainless steel ropes.

- Applications: Loading and unloading cargo on ships and offshore platforms.

- Bull Rope Advantage: Bull Rope’s hot-dip galvanized and stainless steel options ensure durability in harsh marine environments, meeting the demands of deck cranes.

-

Rough Terrain Cranes

- Characteristics: High-strength ropes with fatigue resistance for uneven ground.

- Preferred Construction: 6x36 or compacted ropes.

- Applications: Construction sites with challenging terrain.

- Bull Rope Advantage: Bull Rope’s robust compacted and 6x36 constructions provide the strength and durability required for rough terrain crane operations.

-

Telescopic Cranes

- Characteristics: Flexible ropes capable of handling dynamic loads.

- Preferred Construction: Rotation-resistant ropes (19x7 or 35x7).

- Applications: Mobile lifting operations, urban construction, and emergency rescue.

- Bull Rope Advantage: Bull Rope’s anti-rotation ropes, like 19x7 and 35x7, offer superior load stability for telescopic crane tasks.

-

Hammerhead Cranes (Giant Cantilever Cranes)

- Characteristics: Anti-rotation ropes with high strength for precision lifting.

- Preferred Construction: 19x7 or compacted ropes.

- Applications: Dockyards, shipbuilding, and large construction projects.

- Bull Rope Advantage: Bull Rope’s compacted and anti-rotation ropes provide stability and accuracy, ensuring efficiency in hammerhead crane operations.

-

Monorail Cranes

- Characteristics: Flexible and lightweight ropes for moderate lifting.

- Preferred Construction: 6x19 or 6x36.

- Applications: Warehousing, assembly lines, and light industrial use.

- Bull Rope Advantage: Bull Rope’s 6x19 and 6x36 options provide the necessary flexibility and reliability for monorail crane systems.

-

Luffing Jib Cranes

- Characteristics: High-strength and anti-rotation ropes for dynamic loads.

- Preferred Construction: 19x7 or compacted ropes.

- Applications: High-rise building construction and dense urban sites.

- Bull Rope Advantage: Bull Rope’s anti-rotation ropes ensure stability and precision, making them ideal for luffing jib cranes in restricted spaces.

-

Rail-Mounted Cranes

- Characteristics: Durable, high-tensile ropes with resistance to fatigue.

- Preferred Construction: 6x36 or hot-dip galvanized ropes.

- Applications: Ports, container terminals, and industrial facilities.

- Bull Rope Advantage: Bull Rope offers high-tensile and corrosion-resistant ropes that ensure reliable performance for rail-mounted cranes.

-

Container Cranes

- Characteristics: High-capacity ropes with superior corrosion resistance.

- Preferred Construction: Stainless steel or hot-dip galvanized ropes.

- Applications: Ports and container terminals.

- Bull Rope Advantage: Bull Rope’s stainless steel and galvanized options deliver strength and durability for container crane applications.

Bull Rope: The Ideal Choice for Crane Applications

Bull Rope stands out in the industry by providing steel wire ropes with exceptional quality, durability, and performance. Each product is engineered to meet the demands of specific crane types, ensuring safety, reliability, and efficiency in all lifting operations. For expert guidance and tailored solutions for your crane requirements, contact us today and discover why Bull Rope is the trusted brand for steel wire ropes worldwide!DIFFERENT ROPE CONSTRUCTIONS WITH APPLICATIONS

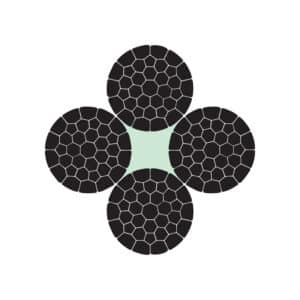

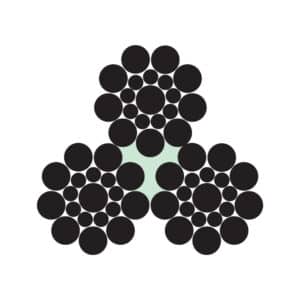

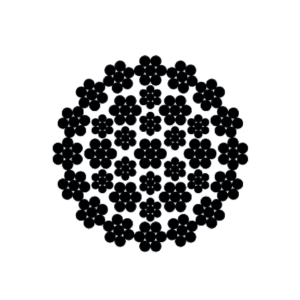

Choosing the right steel wire rope construction is essential for safe and efficient operations. The suggestions below serve as a guide to help you select the best rope for your application, especially when other specific guidance is unavailable. If a particular rope construction does not perform as expected, consider trying an alternative from this list.| Steel Wire Rope Construction | Description | Common Applications | Alternative Suggestions |

| 6x19 Filler (6x25 Fi) | Contains 6 strands with 19 or 25 wires each. Known for its flexibility and moderate resistance to wear. | Derrick and boom cranes, tower crane hoists, dredger boom hoists, and drilling rigs | Consider 6x36 for greater flexibility and fatigue resistance in applications that need endurance. |

| 6x36 | Made of 6 strands with 36 wires each. Highly flexible with strong fatigue resistance, but less abrasion-resistant. | Derrick and boom cranes, tower cranes, dredger ladder hoists | Use 6x19 Filler if you need more abrasion resistance. This option is slightly stiffer. |

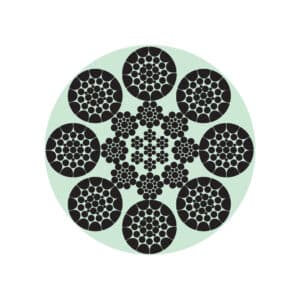

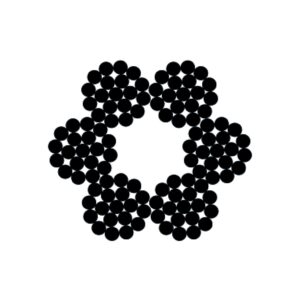

| 18x7 | Features 18 strands with 7 wires each. Offers excellent rotation resistance. | Tower crane hoists, cranes with high lifting requirements | Substitute with 19x7 for similar rotation resistance if extra stability under load is needed. |

| 19x7 | Built with 19 strands of 7 wires each. Provides high rotation resistance, often used to minimize twisting. | Tower crane hoists, cranes where anti-rotation is essential | Try 18x7 as an alternative for moderate rotation resistance needs. |

| 6x19 Seale | A single layer of larger outer wires provides higher resistance to wear with moderate flexibility. | Drilling rigs, heavy-duty applications | Consider 6x36 if you prioritize flexibility and fatigue life over abrasion resistance. |

| 6x7 Galvanized | 6 strands of 7 wires, typically galvanized for corrosion protection. | Sand coring, swabbing, and marine applications | For added durability, consider a plastic-coated option to improve corrosion resistance. |

| 6x21 Filler | Often has 6 strands with filler wires, usually left-hand lay, offering moderate flexibility and abrasion resistance. | Percussion drilling rigs | Use 6x25 Fi or similar constructions for slightly better fatigue resistance. |

| 6x21 Seale | Similar to 6x19 but with slightly higher wear resistance due to the Seale arrangement. | General lifting, cranes | Use 6x36 for more flexibility and fatigue resistance if needed. |

| 6x36 Filler Wire | High-flexibility construction with 36 wires per strand, ideal for environments needing strong endurance against bending fatigue. | Heavy lifting, hoisting, and high-flex applications | For higher wear resistance, try 6x19 with slightly less flexibility. |

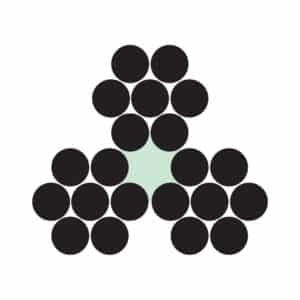

| 7x19 | 7 strands with 19 wires each, providing excellent flexibility, often used for smaller-diameter ropes. | Small pulleys, winches, control cables | Use 6x19 or 6x36 for larger applications that need similar flexibility. |

| Rotation-Resistant Ropes (e.g., 35x7) | Designed to resist rotation under load, with multiple strands that minimize twist. | Cranes, hoisting applications with strict rotation control | 18x7 or 19x7 offer good rotation resistance for less demanding needs. |

Choosing the Right Rope for Your Needs

- Abrasion Resistance: For heavy wear and abrasion, ropes like 6x19 Seale are highly suitable due to their larger outer wires.

- Flexibility: For applications that need frequent bending and high flexibility, constructions like 6x36 are more resilient and reduce fatigue.

- Rotation Resistance: In situations where twisting needs to be controlled, ropes like 19x7 or 35x7 are best. These prevent rotation under load, making them ideal for hoisting and crane applications.

- Corrosion Resistance: For use in wet or corrosive environments, galvanized ropes, such as 6x7 Galvanized, are effective. For extra protection, consider ropes with plastic-coated cores to improve durability.

Problem-Solving Tips

If a particular rope construction is not performing as expected, consider these alternatives:- For greater flexibility and endurance, switch to a construction with more wires per strand, like 6x36.

- If a rope is wearing down too quickly, try a construction with larger outer wires, such as 6x19 Seale, for better wear resistance.

- For environments with heavy twisting, choose a rotation-resistant rope like 19x7 to reduce issues with rotation.

Guidance and Local Support in Dammam, Jubail, and Riyadh

Unsure which steel wire rope construction is best for your project? Our team is here to guide you. With locations in Dammam, Jubail, and Riyadh, we offer tailored advice based on your specific requirements. Our experts understand the unique needs of the region and can help you choose the right rope for your application. Contact us today to schedule a consultation and let our experienced team help you find the best steel wire rope solution. Get the right support from our experts in Dammam, Jubail, and Riyadh to ensure your project’s success. Need assistance? Reach out now to secure your steel wire rope solution!Comparison of Rope Finishes

| Finish Type | Corrosion Resistance | Durability | Flexibility | Cost | Best Use Cases |

| Galvanized Steel | Moderate | High | Moderate | Affordable | Outdoor use, moderate marine environments |

| Stainless Steel | Very High | Very High | High | Expensive | Coastal, offshore, marine, and harsh environments |

| Bright Steel | Low | Moderate | High | Economical | Indoor use, controlled environments |

| Ungalvanized Steel | Very Low | Moderate to Low | High | Low | Indoor use, temporary applications, or where corrosion is not a concern |

Comparison of Bull Rope vs. Competitors

| Feature | Competitors | Bull Rope |

| Strength | High | Very High |

| Flexibility | Low | High |

| Lifespan | Moderate | Very High |

|

Corrosion Resistance

|

Moderate | Very High |

| Price | Expensive | Competitive |

| Applications | General lifting |

Versatile across all industries

|

Ready to Make the Right Choice?

Our Bull Rope offers unmatched performance, strength, and versatility for a wide range of industries, including construction, marine, oil and gas, and beyond. Whether you need help selecting the right rope finish or want to explore how Bull Rope can improve your operations, we’re here to help.STEEL WIRE ROPE STANDARDS

Steel wire ropes must meet certain industry standards to ensure their safety, strength, and reliability. These standards are set by international organizations to guarantee that ropes are fit for specific applications, such as lifting, hoisting, or towing. Some common steel wire rope standards include:- ISO 2408 - This is the international standard for the general requirements of steel wire ropes. It specifies the dimensions, construction, and strength requirements for ropes used in lifting, marine, and other industrial applications.

- EN 12385 - A European standard that defines the safety requirements and testing methods for steel wire ropes. This standard is widely recognized in Europe and covers aspects like construction, performance, and testing.

- ASTM A1023 - This standard from ASTM International is used primarily in the U.S. and sets the requirements for carbon steel wire ropes. It covers specifications for construction, mechanical properties, and testing procedures.

- OSHA Standards (Occupational Safety and Health Administration) - In the U.S., OSHA has specific standards for the use of wire ropes in various applications. This includes ensuring that ropes meet specific performance criteria and are properly maintained.

- API 9A - This standard is from the American Petroleum Institute and applies to steel wire ropes used in the oil and gas industry, particularly for drilling and lifting operations.

- BS 302 - A British standard for steel wire ropes used in mining and industrial applications. It covers the rope’s design, construction, and mechanical properties.

STEEL WIRE ROPE CERTIFICATIONS

To ensure the quality and safety of steel wire ropes, manufacturers often obtain certifications from recognized organizations. These certifications confirm that the ropes meet specific performance and safety criteria. Common steel wire rope certifications include:- ISO Certification - This ensures that the manufacturer meets global quality standards for production, including compliance with ISO 9001 for quality management systems.

- CE Marking - This certification indicates that the steel wire rope meets the health, safety, and environmental protection standards required by the European Union for certain products.

- Bureau Veritas - A global certification provider, Bureau Veritas certifies manufacturers for quality, safety, and environmental management, ensuring ropes meet specific international standards.

- ABS (American Bureau of Shipping) - For ropes used in marine applications, certification by ABS ensures the rope meets specific quality and safety standards for offshore and maritime operations.

- LMQ (Lloyd’s Register Quality Assurance) - Lloyd’s Register offers certifications for the production of steel wire ropes, particularly for applications in demanding industries like oil and gas, mining, and construction.

- TÜV Rheinland - TÜV certification ensures the steel wire ropes comply with specific European safety standards. They also perform regular audits and inspections to ensure quality and compliance.

- AISI Certification - The American Iron and Steel Institute offers certification to steel wire rope manufacturers, ensuring the steel used meets the specified chemical and mechanical properties for different applications.

Why Standards and Certifications Matter

Adhering to steel wire rope standards and obtaining the right certifications is critical for safety and performance. It ensures that the ropes used in industries like construction, mining, marine, and oil & gas can handle the required loads and environmental stresses. For example, using ropes that don’t meet the required standards can lead to accidents, damage, or failure under heavy loads. Sourced from certified facilities in Saudi Arabia, UAE, UK, India and Korea, every rope combines international quality with regional availability. Our steel wire ropes meet all the necessary international standards, including ISO, EN, ASTM, and API, ensuring that you receive reliable and high-performance products. Whether you are in Dammam , Jubail and Riyadh, Saudi Arabia, we provide steel wire ropes that comply with these standards and certifications, offering you peace of mind that your operations are safe, efficient, and up to the highest industry requirements.STEEL WIRE ROPE PRECAUTIONS

Steel wire ropes are essential for many industries, but they need proper care to work safely and efficiently. Taking a few simple precautions can prevent damage, accidents, and ensure the ropes last longer. Here are the key things you should keep in mind:1. Proper Handling

First, always avoid sharp bends. Sharp bends can damage the rope and weaken it. Use larger pulleys or sheaves to avoid putting too much pressure on the rope. Next, never overload the rope. Always respect its working load limits. Overloading can cause the rope to fail. Also, don’t let the rope kink. Kinks can cause hidden damage, which may lead to rope failure.2. Correct Installation

When installing, ensure the rope is aligned properly with pulleys or drums. Misalignment can cause uneven wear. Additionally, when spooling the rope, make sure it is not tangled or overlapping. This will prevent the rope from wearing unevenly and getting damaged.3. Regular Inspections

It’s important to check the rope regularly for signs of wear. Look for broken wires, fraying, or corrosion. If you notice these issues, address them immediately. Especially in outdoor or marine environments, check for rust. If you spot any corrosion, it may be time to replace or treat the rope.4. Lubrication

Lubricating the rope reduces friction and prevents corrosion. Be sure to use the right type of lubricant for your specific rope. However, avoid over-lubricating. Too much lubricant can attract dirt, which can cause the rope to wear faster.5. Safe Storage

Proper storage is just as important. Always store steel wire ropes in a dry place to prevent rust. Keep them away from chemicals or harsh elements. Also, try to store the rope in shaded areas to protect it from direct sunlight. Prolonged exposure to sunlight can weaken the rope’s material.6. Minimize Vibration

Excessive vibration can cause fatigue and weaken the steel wire rope. Make sure the equipment is set up to minimize vibration or shock loads that can damage the rope.7. Protect from Harsh Chemicals

Avoid letting steel wire ropes come in contact with chemicals, oils, or acids. These substances can degrade the rope. If you work in such environments, consider using ropes with protective coatings.8. Follow Manufacturer’s Guidelines

Always follow the manufacturer’s instructions for installation, maintenance, and inspections. These guidelines are designed for the specific rope you are using, ensuring its optimal performance and safety.Why These Precautions Matter

Taking these precautions is crucial for ensuring the safety, longevity, and efficiency of your steel wire ropes. Neglecting them can lead to rope failure, accidents, and costly downtime. If you’re based in Dammam, Jubail and Riyadh, Saudi Arabia, our team can guide you in selecting the right ropes and maintaining them for long-lasting performance.Need Help?

If you’re unsure about how to care for your steel wire ropes, or need expert advice, contact us today. Our team in Dammam and Jubail is always ready to support you with the best practices and products. We are here to help keep your operations running safely and smoothly!TAILORED LENGTHS

Maximize efficiency and minimize waste with ropes cut to your exact specifications.- Custom Lengths: Whether you need short lengths for small machines or extended ropes for large-scale crane operations, we deliver to your precise requirements.

- Reduced Downtime: Pre-cut lengths eliminate the need for on-site adjustments, saving valuable time during installation.

- Efficient Usage: Tailored lengths help avoid waste, ensuring you only pay for what you need.

BULK ORDERS AND DISCOUNTS

At SSTC, we aim to support businesses that rely on steel wire ropes for their daily operations. For companies with large-scale needs, we offer exclusive pricing and loyalty benefits to make your purchases more cost-effective while building lasting partnerships.Special Pricing for Bulk Orders

- Bulk Discounts: Save significantly when you order in larger quantities, ideal for industries like construction, shipping, and oil and gas.

- Tailored Packages: Customize your order with different rope finishes, lengths, and constructions while still benefiting from bulk pricing.

- Fleet Solutions: Shipping companies and fleets can enjoy special pricing for ropes used in mooring, towing, and offshore operations.

Loyalty Programs for Repeat Clients

- Exclusive Rewards: Repeat customers gain access to perks such as free maintenance consultations, helping you keep your ropes in top condition.

- Priority Support: Enjoy faster processing for orders and priority access to new product launches.

- Customized Discounts: Special loyalty pricing tailored to your usage and industry requirements.

Frequently Asked Questions (FAQs)

General Questions

- What is a steel wire rope, and how is it made? A steel wire rope is a strong, flexible rope made of multiple strands of steel wires twisted into a helical shape. It typically includes a core (fiber or steel) for support and stability.

- Where are steel wire ropes commonly used? Steel wire ropes are used in construction, marine, mining, oil and gas, forestry, agriculture, transportation, and rescue operations for lifting, pulling, and securing heavy loads.

- What are the key factors to consider when choosing a steel wire rope?

Consider:

- Load capacity and safety factor.

- Flexibility and abrasion resistance.

- Rope construction (e.g., 6x19, 6x36).

- Core type (fiber core or steel core).

Technical and Maintenance Questions

- What is the difference between breaking strength and working load limit (WLL)?

- Breaking Strength: The maximum load a rope can handle before breaking.

- Working Load Limit: A safety margin (usually 1/5th or 1/6th of the breaking strength) to ensure safe operation under regular conditions.

- How do I properly measure the diameter of a steel wire rope? Use a caliper to measure across the outermost crowns (highest points) of two opposite strands. Avoid measuring across valleys, as this gives an inaccurate, smaller reading.

- What is the lifespan of a steel wire rope? The lifespan depends on usage, maintenance, and environmental factors. Regular inspections and proper lubrication can extend its life significantly.

- How often should steel wire ropes be inspected? Critical applications: Before each use. General use: At least every 3 months. Look for broken wires, corrosion, wear, or deformation.

- What causes steel wire ropes to fail?

Common causes include:

- Overloading beyond the WLL.

- Corrosion from exposure to moisture or chemicals.

- Kinks or improper handling.

- Abrasion from rough surfaces or sharp bends.

- How should I lubricate steel wire ropes? Use a lubricant designed for steel wire ropes that can penetrate the core. Apply evenly to reduce friction and protect against corrosion.

Specific Product and Feature Questions

- What are the benefits of PVC-coated steel wire ropes?

PVC-coated ropes offer:

- High corrosion resistance.

- Extra durability and protection.

- Applications in marine environments, fencing, and industrial winches.

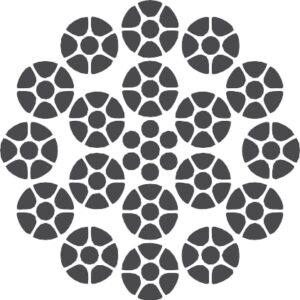

- What is a compacted steel wire rope? A compacted rope has strands compressed during manufacturing to increase strength, reduce wear, and improve fatigue resistance. It’s ideal for heavy-duty applications like cranes and mining.

- What is hot-dip galvanized steel wire rope? This rope is coated in molten zinc for superior corrosion resistance, making it suitable for outdoor and marine environments.

- What’s the difference between Lang’s Lay and Ordinary Lay ropes?

- Lang’s Lay: Wires and strands twist in the same direction, offering better wear resistance.

- Ordinary Lay: Wires twist in the opposite direction to the strands, providing greater stability and less untwisting under load.

- What are rotation-resistant ropes, and when should I use them? Rotation-resistant ropes (e.g., 19x7 or 35x7) minimize twisting under load. Use them for crane operations or applications requiring anti-twisting properties.

- Which finish should I choose for my application?

- Bright Steel: For indoor use.

- Galvanized Steel: For outdoor use with moderate corrosion resistance.

- Stainless Steel or Hot-Dip Galvanized: For high corrosion resistance in marine or harsh environments.

Cost and Availability Questions

- How is the cost of a steel wire rope determined?

Factors include:

- Diameter and length.

- Construction and core type.

- Finish (galvanized, stainless steel, PVC-coated).

- Special features like compacting or rotation resistance.

- Do you offer custom lengths or bulk discounts? Yes, we provide custom lengths tailored to your needs and offer bulk discounts for large orders. Contact us for more details.

- Are your ropes certified?

Yes, our steel wire ropes meet international standards such as:

- ISO 2408

- EN 12385

- ASTM A1023 Certifications from ABS, Bureau Veritas, and Lloyd’s Register are also available.

Safety and Environmental Questions

- What safety factor should I use for my application?

- Elevators: 10:1

- Cranes/Hoists: 6:1

- Guy Wires: 4:1

- Aerial Ropeways: 3:1

- Can steel wire ropes be used in extreme temperatures? Yes, but the rope must be rated for specific temperature ranges. Stainless steel and hot-dip galvanized ropes perform well in both high and low temperatures.

- How do I store steel wire ropes to prevent damage?

- Store in a clean, dry area.

- Keep away from moisture, chemicals, and direct sunlight.

- Use reels or racks to avoid kinks or tangling.

- What precautions should I take during steel wire rope handling?

- Avoid dragging ropes across rough surfaces.

- Prevent kinks by coiling ropes properly.

- Use proper tools to cut and splice ropes.

Troubleshooting and Replacement Questions

- How do I know when to replace a steel wire rope?

Replace the rope if you notice:

- Broken wires exceeding allowable limits.

- Severe corrosion or rust.

- Flattening, fraying, or significant diameter reduction.

- Visible kinks or deformations.

- What should I do if my rope shows signs of wear?

- Stop using the rope immediately.

- Inspect for internal and external damage.

- Consult an expert for possible repairs or replacement.

- Can I repair a damaged steel wire rope? Minor damages like loose strands can sometimes be repaired by splicing, but severe damage (e.g., broken wires or corrosion) requires replacement.

Why Choose Us?

Our Bull Rope steel wire rope offers top-tier quality and performance, comparable to industry-leading brands like Casar, DSR, Lankhorst, Bridon, Brunton Wolf, and Kiswire. Whether you need a reliable solution for lifting, hoisting, or pulling, our Bull Rope stands out for its exceptional strength, durability, and resistance to wear. We ensure that it meets the highest standards, providing you with the same level of reliability and efficiency you expect from these renowned names in the industry. Choose our Bull Rope for a trusted, high-quality alternative that delivers outstanding results every time. As a trusted distributor of Bull steel wire ropes in Dammam, Jubail and Riyadh. we understand the needs of local industries. We offer a wide selection of high-quality ropes to suit different applications. Our team is here to help you choose the right rope and provide maintenance tips to keep it in top condition. Contact us today to learn more about how we can support your projects and ensure you have the best solutions for your lifting and securing needs.If you couldn’t find the product you need , don’t worry! Fill out the form below, and our team will assist you in finding the perfect match. Your satisfaction is our priority.

Related products

Viewed Products

Filter by price

Filter by

Product Status

Filter by brand

- Polyester Web Slings

- Wire Rope Slings

- Chain Sings

- Steel Wire Rope

- Wire Rope Fittings

- Block / Hoist / Trolley

- Shackles

- Fall Protection

- Chains

- Hooks

- Material Handling Equipment

- Cargo Accessories

- Lifting Clamps

- Rigging Screws

- Stainless Steel Accessories

- Safety Shoes

- Polypropylene Rope

- High Strength Polypropylene Rope

- Polyester Rope

- Polyamide Nylon Rope