Rope fitting failures are a critical concern in various industries, from construction and marine operations to manufacturing and transportation. At Safe and Secure Trading Company (SSTC), we’ve seen firsthand the devastating consequences that can arise from neglecting proper inspection and maintenance of these vital components. Understanding the causes and prevention methods for rope fitting failures is paramount for ensuring the safety of personnel and the integrity of operations.

Understanding Rope Fitting Failures

Rope fitting failures encompass a range of issues that can compromise the integrity and functionality of rigging systems. These failures can stem from various factors, including material defects, improper installation, overloading, corrosion, and inadequate maintenance. Identifying the root cause of a failure is crucial for preventing future incidents.

[IMAGE: A split sheave on a crane, with a wire rope that has popped out of the sheave and is now kinked and frayed. Close-up view.]

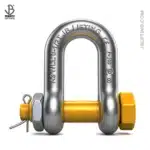

At SSTC, we emphasize the importance of understanding the different types of rope fittings and their specific applications. Cable fittings, such as swage fittings, wire rope clips, and shackles, each have unique strengths and limitations. Selecting the appropriate fitting for the intended load and environmental conditions is essential. We’ve observed instances where using an incorrect fitting, even if it appears similar, has led to catastrophic consequences.

Common Causes of Rope Fitting Failures

Several factors contribute to rope fitting failures. A comprehensive understanding of these causes enables proactive mitigation strategies.

Material Defects

Material defects can compromise the inherent strength of a rope fitting. These defects may arise during the manufacturing process, including issues with casting, forging, or heat treatment. Such defects can include internal cracks, voids, or inconsistencies in the material’s microstructure.

At SSTC, our quality control processes involve rigorous inspection of rope fittings to detect any material defects. We utilize non-destructive testing methods, such as ultrasonic testing and magnetic particle inspection, to identify subsurface flaws that may not be visible to the naked eye. Catching these defects early is crucial to prevent premature failure.

Improper Installation

Improper installation is a significant contributor to rope fitting failures. Errors during installation can introduce stress concentrations, misalignments, or inadequate clamping forces, all of which can significantly reduce the fitting’s load-bearing capacity.

One common mistake we often see is overtightening wire rope clips. Overtightening can crush the wire rope, damaging individual strands and reducing its overall strength. Conversely, undertightening can allow the rope to slip, leading to instability and potential failure. Another installation issue arises with swage fittings. If not swaged correctly, the fitting will not hold the proper load and can slip right off of the cable.

[IMAGE: Diagram showing the correct and incorrect ways to install wire rope clips, highlighting the saddle placement and torque specifications.]

Overloading

Exceeding the Safe Working Load (SWL) of a rope fitting is a direct path to failure. Overloading introduces excessive stress on the fitting, leading to deformation, cracking, or complete rupture. It’s vital to accurately assess the load requirements and select fittings with appropriate SWL ratings.

In our experience, many overloading incidents occur due to a lack of awareness or miscalculation of the actual load being applied. Factors such as dynamic loading, impact forces, and uneven weight distribution must be considered when determining the appropriate SWL. Rigorous load testing can help verify the capacity of the system.

Corrosion

Corrosion is a insidious threat to rope fittings, particularly in marine and offshore environments. Exposure to saltwater, humidity, and corrosive chemicals can degrade the material, weakening its structural integrity. Corrosion can manifest as surface rust, pitting, or intergranular attack.

Preventing corrosion requires implementing proactive measures, such as applying protective coatings, using corrosion-resistant materials, and implementing regular cleaning and lubrication programs. Our team in Dubai often encounters severe corrosion issues due to the region’s harsh marine environment.

Inadequate Maintenance

Lack of proper maintenance can accelerate the deterioration of rope fittings. Regular inspections, cleaning, and lubrication are essential for preserving their integrity and extending their service life. Neglecting maintenance can lead to undetected damage, accelerated corrosion, and eventual failure.

A client once asked us about this… They wanted to know why their rigging equipment was failing prematurely despite being relatively new. We showed them how implementing a simple maintenance schedule, including regular cleaning and lubrication, led to a measurable lift in the equipment’s lifespan and a reduction in downtime.

Abrasion

Rope fittings are often subjected to abrasion from contact with other surfaces. This is especially true in situations where the rope is dragged over sharp edges or abrasive materials. Abrasion can gradually wear away the fitting, reducing its cross-sectional area and weakening its strength.

Fatigue

Cyclic loading, even within the SWL, can lead to fatigue failure over time. Repeated stress cycles can initiate microscopic cracks that propagate gradually until the fitting eventually fails. The rate of fatigue crack growth depends on the load magnitude, frequency, and material properties.

“The key to preventing fatigue failures is to minimize stress concentrations and ensure that the fittings are properly maintained and inspected.” – John Smith, Lead Safety Inspector

Case Studies of Rope Fitting Failures

Examining real-world examples of rope fitting failures provides valuable lessons for preventing future incidents. Here are a few illustrative case studies:

Case Study 1: Crane Accident Due to Swage Fitting Failure

In 2026, a crane accident occurred at a construction site due to the failure of a swage fitting on the crane’s hoist cable. The investigation revealed that the fitting had not been properly swaged during installation, resulting in insufficient clamping force. As the crane lifted a heavy load, the fitting slipped, causing the load to drop and resulting in significant property damage.

This incident highlighted the critical importance of proper installation procedures and qualified personnel. We always recommend that swaging be performed by certified technicians using calibrated equipment.

Case Study 2: Rigging Failure in Marine Operations

A rigging failure occurred during a marine salvage operation when a shackle connecting a tow line to a disabled vessel fractured. The subsequent investigation revealed that the shackle had been subjected to saltwater corrosion, which had significantly weakened its structural integrity. The corrosion had not been detected during routine inspections due to inadequate cleaning and inspection procedures.

This case emphasized the need for thorough corrosion prevention measures and comprehensive inspection protocols, particularly in marine environments.

Case Study 3: Lifting Equipment Failure Due to Wire Rope Clip Slippage

A worker was injured when a load suspended from a lifting beam fell. The wire rope clips securing the rope to the beam had not been properly tightened during installation. The clips gradually loosened under load, leading to slippage and eventual failure.

This incident underscored the importance of following manufacturer’s instructions for installation and conducting regular inspections to ensure that all fasteners are properly tightened.

[IMAGE: A forensic photo of a failed wire rope clip, showing signs of slippage and deformation.]

Prevention Strategies for Rope Fitting Failures

Preventing rope fitting failures requires a multi-faceted approach encompassing design considerations, material selection, installation practices, inspection procedures, and maintenance protocols.

Proper Design and Material Selection

Selecting the appropriate rope fittings for a specific application is paramount. This involves considering factors such as the load requirements, environmental conditions, and operating frequency. It’s also essential to choose fittings made from high-quality materials that are resistant to corrosion and fatigue.

Our engineering team at SSTC can assist clients in selecting the optimal rope fittings for their specific needs, ensuring that they meet all relevant safety standards and performance requirements.

Qualified Installation and Training

Proper installation is crucial for ensuring the integrity of rope fittings. Installation should be performed by qualified personnel who have been properly trained in the correct procedures. Training programs should cover topics such as torque specifications, alignment techniques, and inspection criteria.

We offer comprehensive training programs for technicians and operators involved in the installation and maintenance of rope fittings. These programs provide hands-on instruction and practical guidance on best practices.

Regular Inspections

Regular inspections are essential for detecting potential problems before they lead to failures. Inspections should be conducted by qualified personnel using appropriate tools and techniques. Inspection criteria should be based on manufacturer’s recommendations and industry best practices.

Inspections should focus on identifying signs of wear, corrosion, damage, and deformation. Any suspect fittings should be removed from service immediately and replaced with new ones.

Load Testing

Load testing is a valuable tool for verifying the capacity and integrity of rope fitting assemblies. Load testing involves subjecting the assembly to a specified load, typically exceeding the SWL, to ensure that it can withstand the anticipated stresses.

We provide load testing services at our facilities, using calibrated equipment and experienced technicians. Load testing can help identify potential weaknesses and ensure that the assembly meets all performance requirements.

Maintenance Protocols

Implementing a comprehensive maintenance program is essential for extending the service life of rope fittings. Maintenance should include regular cleaning, lubrication, and inspection. Protective coatings should be applied to prevent corrosion.

Maintenance schedules should be tailored to the specific operating conditions and environmental factors. Records should be maintained to track maintenance activities and identify potential trends.

Risk Assessment

Conducting a thorough risk assessment can help identify potential hazards associated with rope fitting applications. The risk assessment should consider factors such as the likelihood of failure, the severity of the consequences, and the effectiveness of existing controls.

Based on the risk assessment, appropriate mitigation measures can be implemented to reduce the risk of failure. These measures may include engineering controls, administrative controls, and personal protective equipment.

[IMAGE: A technician performing a detailed visual inspection of a wire rope using a magnifying glass, checking for broken strands and wear.]

Industry Standards and Regulations

Several industry standards and regulations govern the design, manufacture, and use of rope fittings. Adhering to these standards is essential for ensuring safety and compliance.

ASME Standards

The American Society of Mechanical Engineers (ASME) publishes numerous standards related to lifting and rigging equipment, including rope fittings. These standards cover topics such as design requirements, material specifications, and testing procedures.

OSHA Regulations

The Occupational Safety and Health Administration (OSHA) has regulations that address the safe use of lifting and rigging equipment in the workplace. These regulations require employers to provide a safe working environment and to ensure that equipment is properly inspected and maintained.

ISO Standards

The International Organization for Standardization (ISO) also publishes standards related to rope fittings. These standards are widely recognized and used internationally.

Understanding and complying with these standards and regulations is crucial for preventing accidents and ensuring the safety of personnel.

Common Misconceptions about Rope Fittings

There are several common misconceptions about rope fittings that can lead to unsafe practices. Addressing these misconceptions is essential for promoting a culture of safety.

One common myth is that all rope fittings are interchangeable. This is simply not true. Different types of fittings are designed for specific applications and have varying load capacities. Using an incorrect fitting can compromise the integrity of the system.

Another misconception is that rope fittings are maintenance-free. In reality, all rope fittings require regular inspection and maintenance to ensure their continued safe operation. Neglecting maintenance can lead to undetected damage and eventual failure.

Finally, some people believe that overloading a rope fitting slightly is acceptable. However, even a small overload can significantly reduce the fitting’s lifespan and increase the risk of failure. It is crucial to always adhere to the SWL ratings.

The Role of Technology in Improving Rope Fitting Safety

Advancements in technology are playing an increasingly important role in improving rope fitting safety. These technologies include:

- Non-destructive testing (NDT): NDT methods, such as ultrasonic testing and magnetic particle inspection, can detect subsurface flaws and defects that may not be visible to the naked eye.

- Smart sensors: Smart sensors can be integrated into rope fittings to monitor load, strain, and temperature. This data can be used to detect potential overloads or other abnormal conditions.

- Digital inspection tools: Digital inspection tools, such as handheld scanners and drones, can streamline the inspection process and improve the accuracy of inspections.

- Simulation software: Simulation software can be used to model the behavior of rope fittings under different loading conditions, allowing engineers to optimize designs and identify potential weaknesses.

By leveraging these technologies, we can enhance the safety and reliability of rope fittings and reduce the risk of accidents.

Training and Certification Programs

Investing in training and certification programs for personnel involved in the installation, inspection, and maintenance of rope fittings is essential for promoting safety and competency. These programs provide individuals with the knowledge and skills necessary to perform their jobs safely and effectively.

We offer a range of training and certification programs that cover topics such as:

- Rope fitting types and applications

- Installation procedures

- Inspection techniques

- Maintenance protocols

- Load testing procedures

- Risk assessment

Our programs are designed to meet the needs of various industries and organizations.

Conclusion

Understanding the causes and prevention of rope fitting failures is crucial for ensuring the safety of personnel and the integrity of operations. By implementing the strategies outlined in this article, organizations can significantly reduce the risk of accidents and improve the reliability of their rigging systems. Remember to always prioritize safety and adhere to industry best practices. We are confident that a proactive approach to rope fitting safety will lead to a safer and more productive work environment.

FAQ Section

Q: How often should rope fittings be inspected?

A: The frequency of inspections depends on the operating conditions and the severity of the application. As a general guideline, rope fittings should be inspected at least monthly, or more frequently if they are subjected to harsh environments or heavy use.

Q: What are the signs of a failing rope fitting?

A: Signs of a failing rope fitting can include:

- Visible corrosion

- Cracks or deformation

- Excessive wear

- Slippage or loosening

- Broken strands or wires

Any fitting exhibiting these signs should be removed from service immediately.

Q: Can I repair a damaged rope fitting?

A: In general, it is not recommended to repair damaged rope fittings. Damaged fittings should be replaced with new ones that meet the appropriate specifications.

Q: What is the Safe Working Load (SWL)?

A: The Safe Working Load (SWL) is the maximum load that a rope fitting is designed to carry safely. It is important to never exceed the SWL of a fitting.

Q: How can I prevent corrosion on rope fittings?

A: Corrosion can be prevented by:

- Applying protective coatings

- Using corrosion-resistant materials

- Implementing regular cleaning and lubrication programs

- Storing fittings in a dry environment

Q: What is load testing and why is it important?

A: Load testing is a process of subjecting a rope fitting assembly to a specified load to verify its capacity and integrity. Load testing is important because it can help identify potential weaknesses and ensure that the assembly meets all performance requirements.

Q: What are wire rope clips and how should they be installed?

A: Wire rope clips are used to secure the end of a wire rope to form an eye or to connect two lengths of wire rope together. They must be installed correctly with the “saddle” on the live end of the rope and tightened to the manufacturer’s recommended torque.

Q: What are swage fittings and what are their advantages?

A: Swage fittings are cable fittings that are permanently attached to wire rope or cable by cold-forming the metal around the rope. They offer high strength and reliability when properly installed.

Q: How do crane accidents relate to rope fitting failures?

A: Crane accidents are sometimes caused by rope fitting failures due to overloading, improper installation, or lack of maintenance of the wire rope and associated fittings. Regular inspection and adherence to safe lifting practices are crucial.

Q: What is the importance of safety inspections for lifting equipment?

A: Safety inspections are vital for identifying potential hazards and ensuring that lifting equipment, including ropes and fittings, is in safe working condition. Regular inspections help prevent accidents and protect workers.

Q: What should be included in a maintenance program for rigging equipment?

A: A maintenance program should include regular cleaning, lubrication, inspection, and replacement of worn or damaged components. Records of maintenance activities should be maintained to track equipment condition and identify trends.

Q: How does improper installation contribute to rigging failures?

A: Improper installation can introduce stress concentrations, misalignments, or inadequate clamping forces, all of which can significantly reduce the fitting’s load-bearing capacity and lead to rigging failures.

Q: What are the risks associated with using damaged wire rope?

A: Using damaged wire rope increases the risk of failure, leading to potential accidents, injuries, and property damage. Damaged wire rope should be removed from service and replaced immediately.